Aqueous Enteric Coating

1200 INR/Kilograms

Product Details:

- Heavy Metal (%) <0.002%

- Loss on Drying <5%

- Particle Size 90-150 Microns

- Taste Tasteless

- Shelf Life 36 months Months

- Solubility Insoluble in water; dispersible under alkaline pH

- Color White to Off-white

- Click to View more

X

Aqueous Enteric Coating Price And Quantity

- 5 Kilograms

- 1200 INR/Kilograms

Aqueous Enteric Coating Product Specifications

- <5%

- <0.002%

- >98%

- 90-150 Microns

- Tasteless

- Aqueous Enteric Coating

- Pharmaceutical Coating Polymer

- 36 months Months

- Insoluble in water; dispersible under alkaline pH

- Protecting tablets from gastric environment; delayed drug release

- Not available / Mixture

- White to Off-white

- 39100019

- Store in cool, dry place in tightly closed containers

- Odourless

- Pharmaceutical Grade

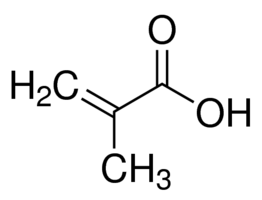

- Acrylic Polymer-based Enteric Coating

- 6.0 7.0 (1% solution)

- Fine White to Off-white Powder

- Non-poisonous

- Powder

- Proprietary / Polymer Blend

- Proprietary blend

- Not available / Above 150C

Aqueous Enteric Coating Trade Information

- Cash Advance (CA), Cash in Advance (CID), Cheque

- 2000 Kilograms Per Month

- 2 - 3 Days

- Yes

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- All India

Product Description

Technical grade Aqueous Enteric Coating is available in 99% pure form. This type of coating material preserves the original quality of pills, tablets and pallets against various external factors. This type of coating is made of minerals present in shellac, waxes, fatty acids and plant fibers. Offered Aqueous Enteric Coating has been formulated under controlled temperature by using quality approved raw materials. Long shelf life, accurate composition, toxin free content and reasonable price are the key aspects of this coating

Specification

|

Purity |

99% |

|

Manufacturing Process |

Readymix tablet coating powder |

|

Grade Standard |

Technical Grade |

|

Type |

Tablet |

Protection and Controlled Drug Release

Aqueous Enteric Coating provides a reliable barrier against gastric fluids, ensuring that any medication reaches the intestinal tract before disintegrating. This enables delayed drug release, enhancing therapeutic efficacy and minimizing gastric irritation. The robust film thickness and pH-responsive breakdown ensure the active ingredients targeted delivery.

Superior Compatibility and Safety

This enteric coating exhibits broad compatibility with a variety of tablet cores and active pharmaceutical ingredients. It is non-poisonous, tasteless, odorless, and conforms to pharmacopeia safety standards, making it suitable for sensitive pharmaceutical applications. The product is easy to handle and meets stringent regulatory requirements for purity and heavy metal content.

Optimized Physical and Chemical Properties

Manufactured as a fine white to off-white powder with particle size ranging from 90-150 microns, this coating maintains integrity under challenging environmental conditions. Its low moisture content, stable viscosity, and suitable glass transition temperature allow for consistent application and storage. The product remains insoluble in water but readily disperses in alkaline pH, ensuring effective enteric protection.

FAQs of Aqueous Enteric Coating:

Q: How is Aqueous Enteric Coating applied to pharmaceutical tablets?

A: Aqueous Enteric Coating is typically dispersed in water under alkaline conditions and applied as a film coating using standard pharmaceutical tablet coating equipment. The recommended film thickness of 4080 microns is achieved through controlled spray or pan coating processes, ensuring uniform coverage and enteric protection.Q: What is the primary benefit of using this enteric coating?

A: The main advantage is its resistance to gastric fluid, which prevents premature release of the drug in the stomach. It ensures tablets disintegrate only in environments with pH higher than 5.5, providing controlled and precise drug delivery to the intestine, improving patient outcomes.Q: When does the coated tablet disintegrate, and why is it important?

A: Coated tablets remain intact in the acidic gastric environment and only disintegrate at pH levels above 5.5, typically found in the intestine. This targeted release profile is vital for medications that can cause gastric irritation or require absorption in the intestinal tract.Q: Where should Aqueous Enteric Coating be stored for optimal shelf life?

A: The product should be stored in cool, dry conditions, tightly closed HDPE drums or multi-layer laminated bags. Proper storage extends shelf life up to 36 months and preserves its physical and chemical properties.Q: Is the coating compatible with most pharmaceuticals and APIs?

A: Yes, the acrylic polymer-based composition is designed to be compatible with most tablet cores and active pharmaceutical ingredients, making it a versatile solution for pharmaceutical manufacturers and formulators.Q: What is the process for ensuring safety and compliance during use?

A: The coating complies with pharmacopeia standards, is non-toxic, and contains less than 0.002% heavy metals, making it safe for use in pharmaceutical applications. Users should follow recommended handling and storage guidelines to maintain product integrity.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email